| As upstream

expression increases bioreactor titers, downstream WFI water usage

increases proportionally. This places increased throughput pressure

on downstream’s existing plant tankage for buffer prep, buffer

storage, and in-process product hold steps.

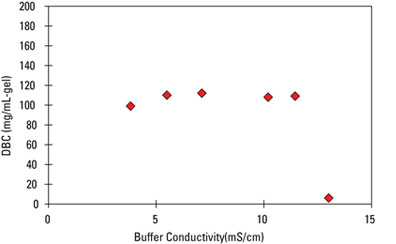

TOYOPEARL GigaCap®

CM-650M resin reduces target elution volumes up to 75%. By maintaining

its 100 g mAb/L dynamic binding capacity in loading conductivities

up to 11 mS/cm (pH 4.7), TOYOPEARL GigaCap CM-650M resin can also

minimize the amount of water needed for feedstock dilution.

The bottom line

is that TOYOPEARL

GigaCap CM-650M resin, when placed early in the chromatographic

purification train, can reduce the amount of WFI water used in subsequent

manufacturing steps.

Buffer conductivity effect on TOYOPEARL GigaCap CM-650M capacity

(polyclonal h-IgG):

Feel free to

email

me if you have any questions or would like to request a sample.

Cordially,

Al Jackewitz

Biopurification Market Manager

Tosoh Bioscience

and TOYOPEARL GigaCap are registered trademarks of Tosoh Corporation.

|