Solujet Low™-Foaming Phosphate-Free Liquid Detergent

Solujet is the detergent to consider for your next new pharmaceutical cleaning

project or when you want to take the opportunity to improve when you are

revalidating your existing cleaning system.

How does Solujet stack up to A LEADING CIP CLEANER?

-

Unlike A LEADING CIP

CLEANER, Solujet

has high wetting surfactants that enhance emulsifying, wetting, dispersing

and rinsing.

The surfactants allow faster, more efficient cleaning and easier rinsing.

-

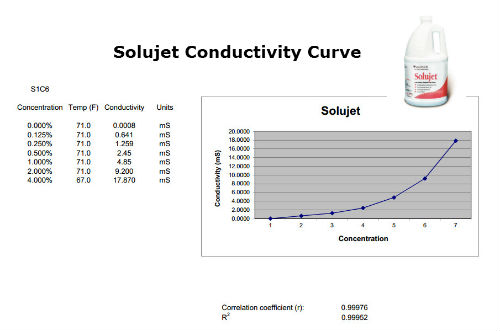

Solujet is recommended

for use at lower concentrations because of the more synergistic surfactant

containing formulation of Solujet which does not rely as much on heavy

alkalinity.

-

A LEADING CIP CLEANER

does not contain an effective wetting agent as seen by the high surface

tension.

-

Both Solujet and A

LEADING CIP CLEANER are potassium hydroxide based cleaners with chelating

agents.

-

Both Solujet and A

LEADING CIP CLEANER are phosphate free and both cleaners are DOT regulated

corrosive liquids.

-

The pH of 1% Solujet

never exceeds 12.5. The pH of 1% A LEADING CIP CLEANER can go as high

as 12.8 according to literature.

-

Although the potassium

hydroxide content of the two cleaners is quite similar, by careful raw

material and manufacturing quality control, the Solujet formulation is

maintained such that a 1% solution will always be below pH 12.5.

Comparison between Solujet and a Leading CIP Cleaner:

|

Product Comparison (1% Solution)

|

Solujet |

A Leading CIP Cleaner |

|

Contains high wetting surfactant

|

Yes |

No |

|

Based on potassium hydroxide and chelates |

Yes |

Yes |

|

DOT regulated corrosive liquid |

Yes |

Yes |

|

Phosphate Free |

Yes |

Yes |

|

Recommended use Concentrations |

1% - 6% |

1% - 6% |

|

Typical surface tension |

33 dynes/cm |

49 dynes/cm |

|

Highest pH in a 1% solution |

<12.5 |

12.8 |

Consider the use of Solujet for cleaning pharmaceutical manufacturing equipment

before the next validation, revalidation or new product launch. Contact

Alconox for validation support to simplify adopting Solujet.

Click here to get a sample.

Click here for a Solujet

technical bulletin.

Optimum Manual Cleaning Detergents in the Pharmaceutical

Process Industry

The disassembled parts and tools used in the pharmaceutical

industry are often cleaned manually in central cleaning rooms. This manual

cleaning is done with validated procedures using training and appropriate record

keeping. The cleaning mechanisms in manual and soak cleaning favor high

emulsifying detergents because longer contact time allows for emulsions to form

in ways that are less likely in high agitation spray clean-in-place cleaning.

Alkaline Liquinox detergent and acidic Citranox detergent are excellent, high

emulsifying cleaners that are commonly used in manual cleaning of pharmaceutical

process equipment, parts and tools. Click here < http://www.alconox.com/Resources/TechnicalBulletin.aspx >

to see the technical data sheet and cleaning validation information.

Sample Offer www.alconox.com/sample21.html

Ask Alconox Offer https://www.alconox.com/request/askalconox.aspx